Glass Lined Reactor

1000-2000L CE Type Glass Lined Reactor

Glass Lined Reactor Introduction

CE type glass lined reactor is a glass rich in silica, lined in the inner surface of the steel vessel, by high temperature burning and firmly dense on the metal surface to become a composite product. Therefore, it has the double advantages of glass stability and metal strength, and is an excellent corrosion-resistant equipment. Closed type reactor is one body and cover, the sealing performance should be good, meanwhile, the stirring paddle in the closed type glass lined reactor of the same volume is not as big as the stirring paddle in the open type reactor due to the limitation of installation size.

Technical Parameters

INNER VESSE | JACKET | |

| MATERIAL | Carbon Steel with Glass Linning | Carbon Steel |

| DESIGN PRESSURE(Mpa) | -0.1 / 0.6 | 0 / 0.6 |

| DESIGN TEMPERATURE(℃) | -19 / 200 | -19 / 200 |

| WORKING TEMPERATURE(℃) | -19 / 200 | |

| GLASS LINED THICKNESS(mm) | 0.8-2.0 | |

RESISTANCE TO SHARP TEMPERATURE VARIATION(℃) | COOL SHOCK 110,HOT SHOCK 120 | |

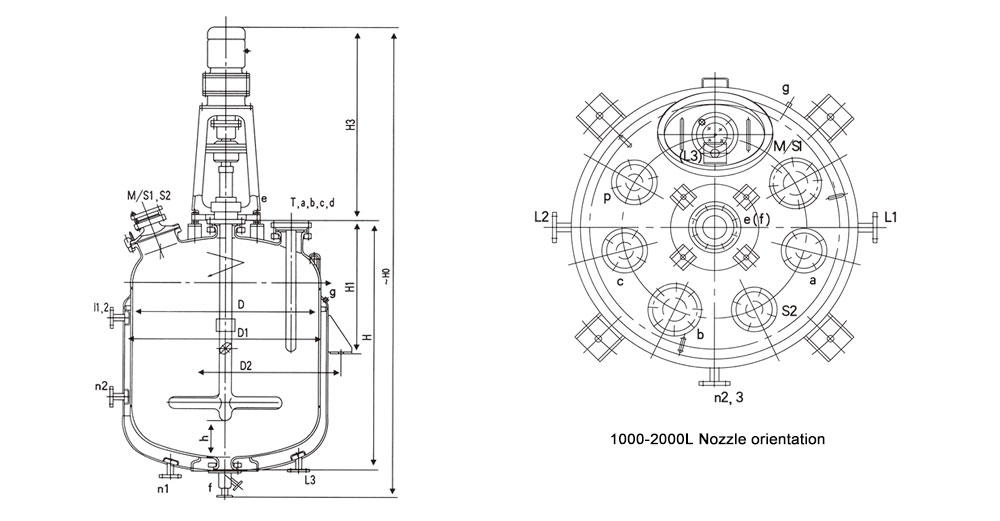

Main Dimensions of CE type Glass Lined Reactor (1000-2000L)

NOMINAL VOLUME (L) | ACTUAL VOLUME (L) | HEAT EXCHANGE AREA(m2) | POWER (Kw) | D (mm) | D1 (mm) | D2 (mm) | D3 (mm) | H (mm) | H1 (mm) | H2 (mm) | H3 (mm) | H0 (mm) | WEIGHT (Kg) |

| 1000 | 1520 | 4.93 | 3 | 1200 | 1300 | 1488 | - | 1610 | 850 | - | 1154 | 3200 | 1837 |

| 1500 | 1961 | 5.35 | 4 | 1300 | 1450 | 1622 | - | 1770 | 870 | - | 1276 | 3486 | 2090 |

| 2000 | 2180 | 7.16 | 4 | 1300 | 1450 | 1622 | - | 2190 | 940 | - | 1276 | 3907 | 2603 |

Nozzle Size of CE type Glass Lined Reactor (1000-2000L)

NOMINAL VOLUME(L) | M | S | P | T | a | b | c | e | f | L1-2 | n1-2 | n3 | n4 |

| 1000 | 400×300 | 100 | 100 | 100 | 100 | 125 | 100 | 125 | 100 | 32 | - | - | - |

| 1500 | 400×300 | 125 | 125 | 100 | 100 | 125 | 100 | 125 | 100 | 40 | 50 | - | - |

| 2000 | 400×300 | 125 | 125 | 150 | 100 | 125 | 100 | 125 | 100 | 40 | 50 | - | - |

Glass Lined Reactor Process Flow

Glass Lined Reactor Advantages

● Used for small, medium and large scale chemical and pharmaceutical production.

● The lid cannot be separated from the tank, which is suitable for the environment with high pressure in the kettle and can avoid or reduce the leakage.

● After removing rust on the surface of reaction kettle, it is sprayed with environmental protection water-based paint, which makes the product more beautiful and environmental friendly.

● Comply with ASTM, ASME, CE, CN standards

● Various non-standard capacities can be designed and customized according to customers' requirements.

Factory Scenes

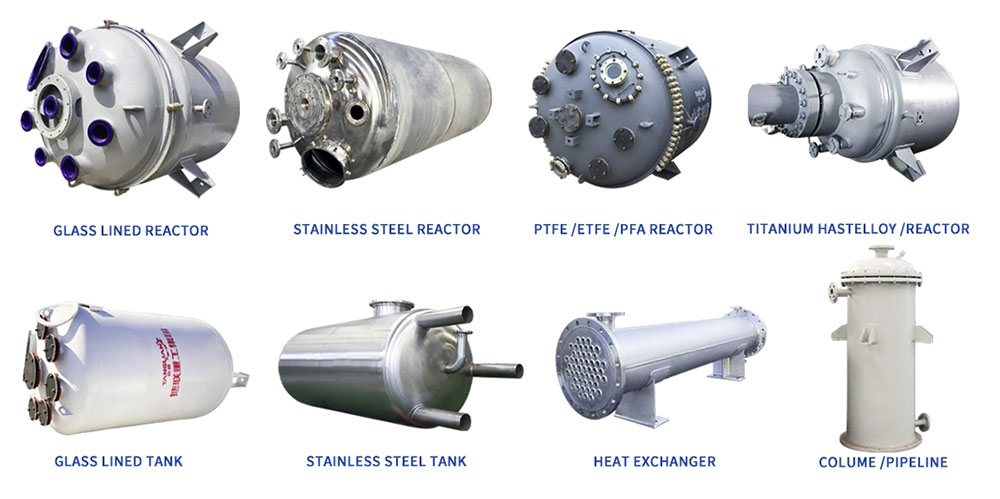

Company Products

Shipping & Installation

International Market

Categories

News

Contact Us

E-mail: service@chinareactor.com

Add: Hongshan Town Industrial Park, Chongzheng Road, Zichuan District, Zibo City, Shandong Province