Glass Lined Reactor

6300L anti acid corrosion Glass Lined/ industrial enamel Chemical Reactor

glass lined equipment Introduction

AE type glass lined equipment is a porcelain enamel rich in silica, lined on the inner surface of the steel vessel, and become a composite product by high temperature firing and firmly dense on the metal surface. Therefore, it has the double advantages of stability of glass and strength of metal, and is an excellent corrosion-resistant equipment. The AE type glass lined equipment in chemical plant is separated by body and cover, and connected by gasket and tank card in the middle, so it is easy to disassemble the open type, and if there is a problem with the pipe opening on the cover, it is easy to remove and repair separately.

Technical Parameters

INNER VESSE | JACKET | |

| MATERIAL | Carbon Steel with Glass Linning | Carbon Steel |

| DESIGN PRESSURE(Mpa) | -0.1 / 0.6 | 0 / 0.6 |

| DESIGN TEMPERATURE(℃) | -19 / 200 | -19 / 200 |

| WORKING TEMPERATURE(℃) | -19 / 200 | |

| GLASS LINED THICKNESS(mm) | 0.8-2.0 | |

RESISTANCE TO SHARP TEMPERATURE VARIATION(℃) | COOL SHOCK 110,HOT SHOCK 120 | |

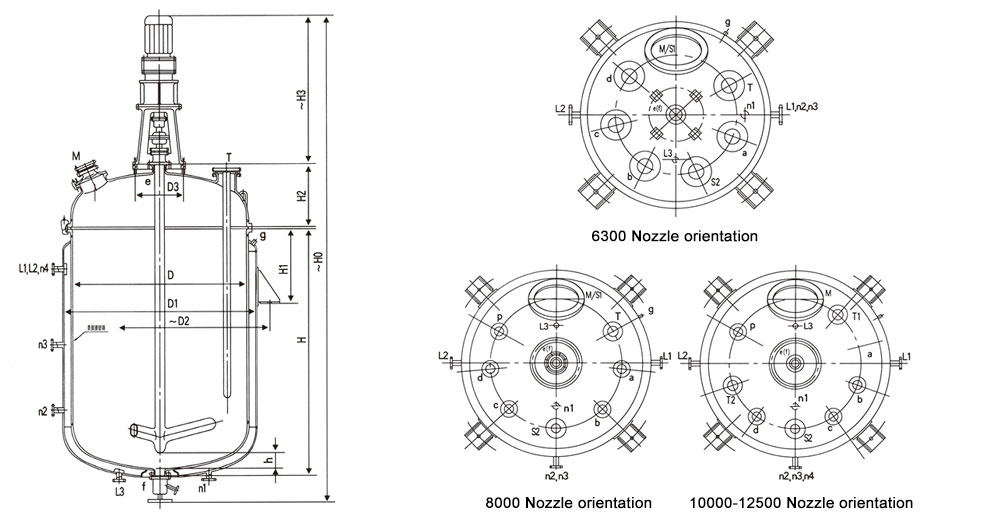

Main Dimensions (6300-12500L)

NOMINAL VOLUME (L) | ACTUAL VOLUME (L) | HEAT EXCHANGE AREA(m2) | POWER (Kw) | D (mm) | D1 (mm) | D2 (mm) | D3 (mm) | H (mm) | H1 (mm) | H2 (mm) | H3 (mm) | H0 (mm) | WEIGHT (Kg) |

| 6300 | 6493 | 15.8 | 7.5 | 1750 | 1900 | 2152 | 450 | 2925 | 700 | 620 | 1395 | 5027 | 5690 |

| 8000 | 8450 | 18.3 | 11.0 | 2000 | 2200 | 2457 | 500 | 2935 | 800 | 705 | 1545 | 5225 | 7576 |

| 10000 | 10520 | 21.15 | 11.0 | 2000 | 2400 | 2708 | 550 | 3040 | 900 | 755 | 1770 | 5588 | 9013 |

| 12500 | 13040 | 25.79 | 15.0 | 2000 | 2400 | 2708 | 550 | 3680 | 900 | 755 | 1770 | 6730 | 10920 |

Nozzle Size (6300-12500L)

NOMINAL VOLUME(L) | M | H | e | T1 | S1 | a | b | c | d | f | n1-2 | n3 | L1-2 |

| 6300 | 300×400 | - | 125 | 125 | 125 | 125 | 150 | 125 | 125 | 125 | 65 | 65 | 70 |

| 8000 | 300×400 | - | 150 | 125 | 125 | 150 | 150 | 150 | 150 | 125 | 65 | 65 | 70 |

| 10000 | 300×400 | - | 200 | 150 | 125 | 150 | 150 | 150 | 150 | 150 | 80 | 80 | 80 |

| 12500 | 300×400 | - | 200 | 150 | 125 | 150 | 150 | 150 | 150 | 150 | 80 | 80 | 80 |

Glass Lined Reactor Process Flow

Advantages

● For small, medium and small scale chemical and pharmaceutical production.

● The lid can be separated from the tank, and a variety of stirrer types can meet the different process needs of users.

● After removing rust on the surface of the chemical reactor, spraying environmental protection water-based paint makes the product more beautiful and environmental friendly.

● Comply with ASTM, ASME, CE, CN standards

● Various non-standard capacities can be designed and customized according to customers' requirements.

Factory Scenes

Shandong Tanglian Heavy Industrial Group , one of the longest established factories for Chemical reactors / Chemical vessels in China .

We have ISO , SGS , CE ,EU Welder Approval Test Certificate for our company , products and workers .

We mainly focus on below products

Chemical reactor , Storage / Receiving / Buffer tank

Column / Tower section , Pipe line

Heat exchanger / condenser , Evaporator

Main material of our equipment :

Glass Lining , PTFE,ETFE,PFA Lining

Stainless Steel , Carbon Steel , Hastelloy , DP Steel

Company Products

Shipping & Installation

International Market

Categories

News

Contact Us

E-mail: service@chinareactor.com

Add: Hongshan Town Industrial Park, Chongzheng Road, Zichuan District, Zibo City, Shandong Province