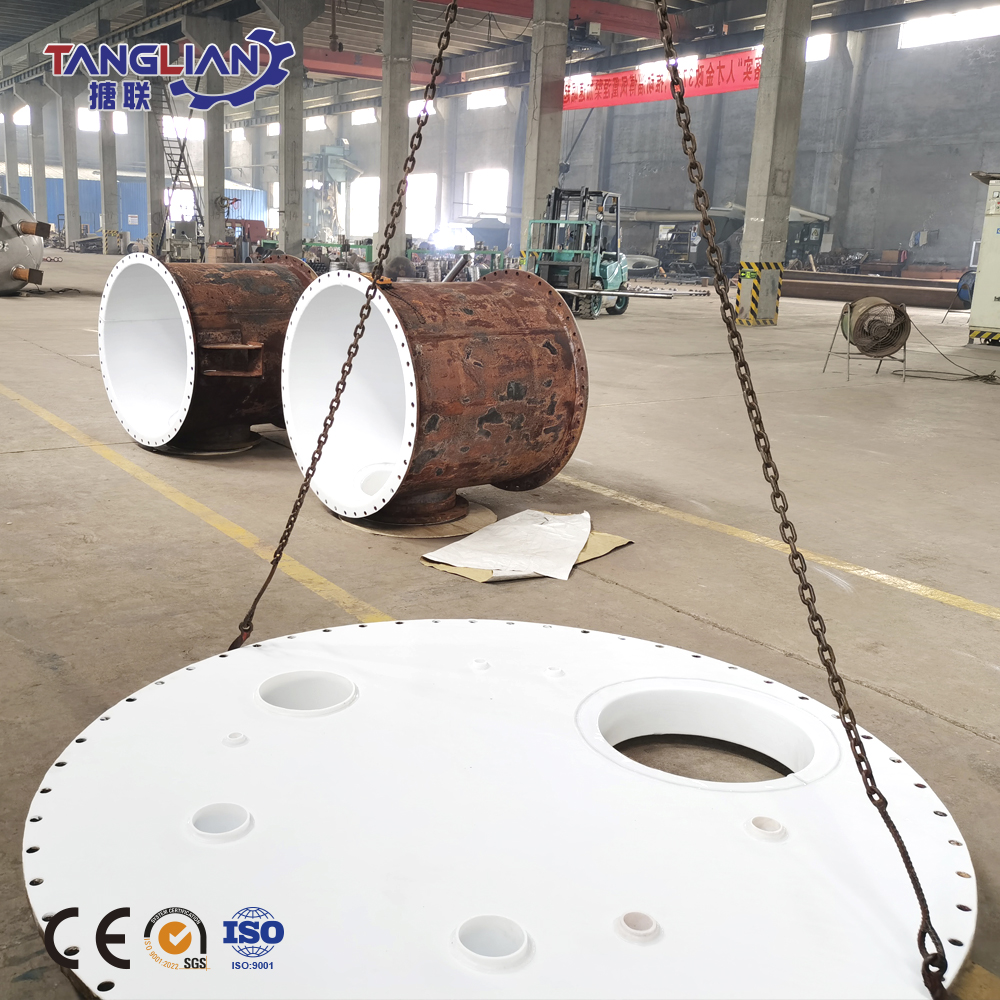

PTFE Lined Storage Tank

Mixing Chemical Equipment PTFE Lined Storage Tank

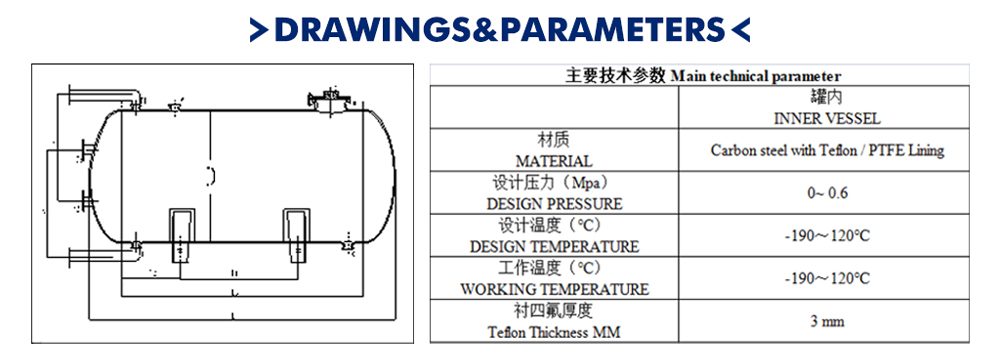

| Main technical parameter | |

| Items. | INNER VESSEL |

| MATERIAL | Carbon steel with Teflon/PTFE Lining |

| DASIGN PRESSURE | 0 ~ 0.6 |

| DESIGN TEMPERATURE | -190 ~ 120℃ |

| WORKING TEMPERATURE | -190 ~ 120℃ |

| TEFLON THICKNESS MM | 3mm |

Horizontal PTFE Lined Storage Tank-Products:

Owing to its low friction, PTFE is used for plain bearings, gears, slide plates, seals, gaskets,bushings and more applications with sliding action of parts, where it outperforms acetal and nylon.

Besides, as one kind of anti corrosive material, PTFE is mainly used lined layer on steel chemical equipment.The tight lining PTFE that has been activated or bonded with a glass fiber cloth with coating by adhesive. At the same time, the steel shell of the equipment is sandblasted and cleaned, painted adhesion. Then the PTFE plate is bonded to the steel body through original vacuum lining technology, which can resist negative pressure up to - 0.095Mpa.

As one of special chemical condition, hot concentrated hydrogen fluoride (HF) solution and hydrochloric acid are highly corrosive, fluorine-containing polymer will be the high corrosive flowing material in tank. Now, one kind of experience reactor that glass-lined layer coate by PTFE option is used on this condition. PTFE make up for the defect of glass-lined resistant fluoride, inner glass lined layer as mainly anti corrosive layer, keeps longer using life because of PTFE.

Product features:

·Clean, high temperature and corrosion resistance ·Smooth and glossy surface, low friction coefficient, not easy to peel off

·excellent penetration resistance

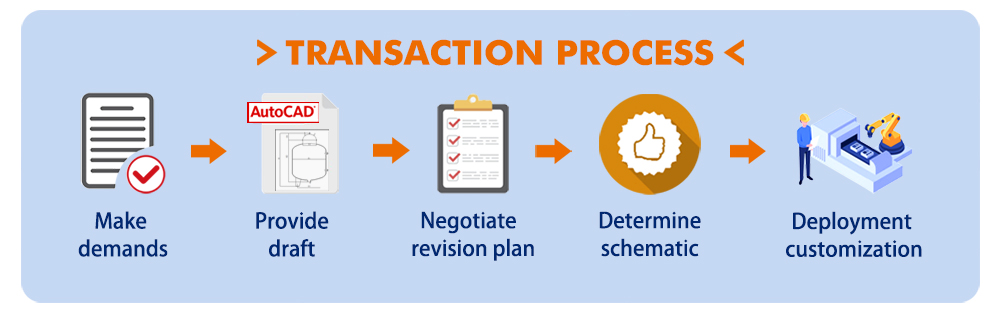

Products can be customized to meet customers’ needs in the aspects of structural design, function, capacity, and various working conditions ,etc.

A series of examinations will be taken before the final fabrication of the product are ready to put into batch production, inspection can be made any time before the final fabrication is ready.

We will provide instant service from the design drawings to after sales constantly upon the feedback from users.

The desgin department provide professional drawings for evaluating feasibility and practicability in the perspective of users.

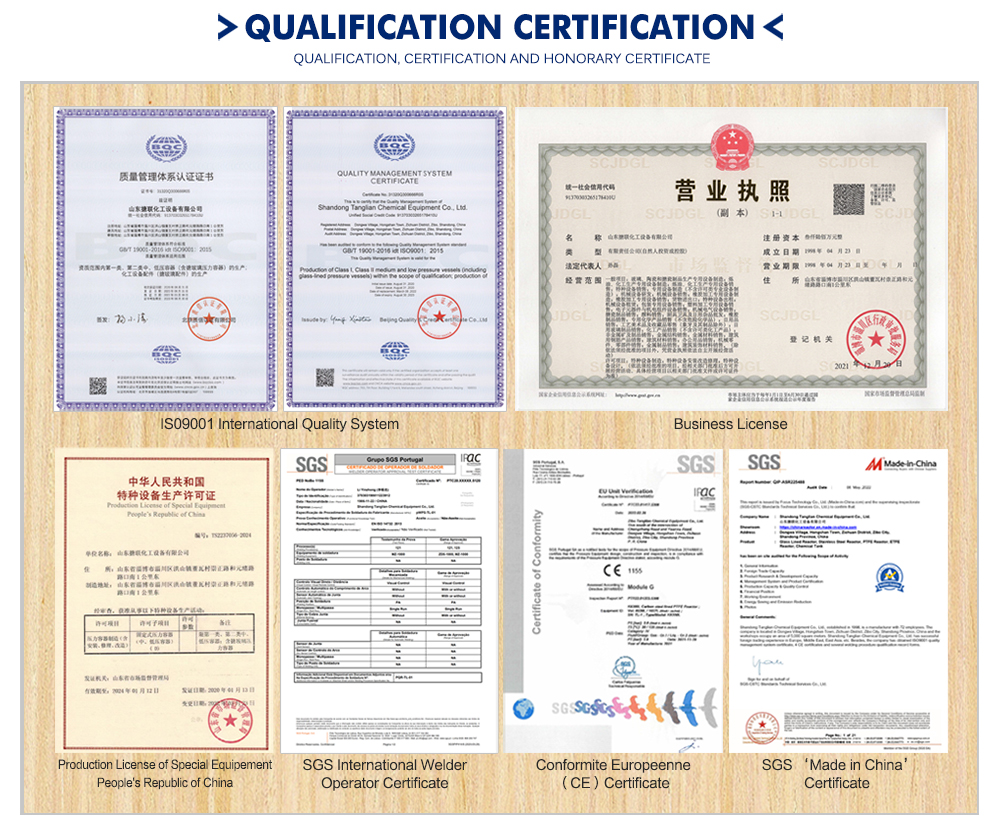

Shandong Tanglian was established in 1998 and is located in Zibo, the hometown of glass lining in China. It is a well-known chemical equipment manufacturer in northern China, specializing in the production of glass-lined reactors, stainless steel reactors, carbon steel reactors and PTFE sparied, PP lining, alloy composite reactor, agitator, storage tank, heat exchanger, shell and tube condenser, tower, film evaporator, vacuum rotary dryer, high pressure laboratory reactor, full-set chemical automatic equipment .The products produced by our company are supplied to the whole china and dozens of foreign countries around the world , and are widely used in petroleum, chemical, pharmaceutical, dye, mining and metallurgy and other fields. The supply objects include enterprises (Qilu Pharmaceuticals, China Wanda, etc.), scientific research institutes (Qingdao Research Institute of Chinese Academy of Sciences, China Sinochem Research Institute, etc.), institutions of higher learning (Harbin Institute of Technology, Dalian Maritime University, etc.), etc.

Categories

News

Contact Us

E-mail: service@chinareactor.com

Add: Hongshan Town Industrial Park, Chongzheng Road, Zichuan District, Zibo City, Shandong Province