Stainless Steel Heat EXchanger

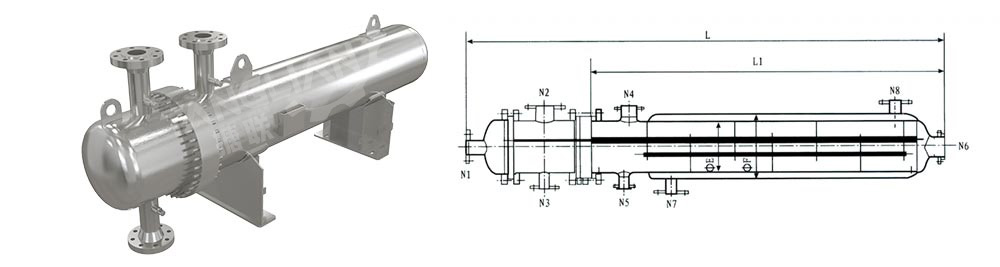

Tubular Heat Exchanger Shell and Tube Type

Tubular Heat Exchanger Shell and Tube Type Introduction

A heat exchanger is a device that transfers part of the heat from a hot fluid to a cold fluid, also known as a heat exchanger. Tubular Heat Exchanger Shell and Tube Type play an important role in chemical, petroleum, power, food, and many other industrial production. They can be widely used as heaters, coolers, condensers, evaporators, and reboilers in chemical production.

Technical Parameters

Tube | Shell | |

| MATERIAL | Stainless Steel 304/316 | Stainless Steel 304/316 |

| DESIGN PRESSURE(Mpa) | -0.1/1.0 Mpa | -0.1/1.0 Mpa |

| WORKING TEMPERATURE(℃) | -196~430 | |

Tubular Heat Exchanger Shell and Tube Type Types: Fixed tube sheet heat exchangers, floating head heat exchangers, U-tube heat exchangers, etc. (processed according to the user's drawings).

Material: Carbon steel, low alloy steel, stainless steel, duplex stainless steel, and various composite plate materials

Shell and Tube Heat Exchanger Advantages

Features: Stainless steel Tubular Heat Exchanger Shell and Tube Type have excellent antioxidant properties, are safe and hygienic, have better heat transfer effects, and have a longer lifespan.

Scope of application: Mainly applicable to industries such as chemical, light industry, metallurgy, pharmaceuticals, food, chemical fiber, etc.

Factory Scenes

Shandong Tanglian Heavy Industrial Group , one of the longest established factories for Chemical reactors / Chemical vessels in China .

We have ISO , SGS , CE ,EU Welder Approval Test Certificate for our company , products and workers .

We mainly focus on below products

Chemical reactor , Storage / Receiving / Buffer tank

Column / Tower section , Pipe line

Heat exchanger / condenser , Evaporator

Main material of our equipment :

Glass Lining , PTFE,ETFE,PFA Lining

Stainless Steel , Carbon Steel , Hastelloy , DP Steel

Company Products

Shipping & Installation

International Market

Categories

News

Contact Us

E-mail: service@chinareactor.com

Add: Hongshan Town Industrial Park, Chongzheng Road, Zichuan District, Zibo City, Shandong Province