Stainless Steel Reactor

50L-50000L Chemical Stainless Steel Tank Mixer Reactor

chemical reactor stainless steel Introduction

chemical reactor stainless steel has the characteristics of heating, high temperature resistance, corrosion resistance, hygiene, no environmental pollution, no boiler automatic heating, easy to use, etc. It is widely used in petroleum, chemical, rubber, pesticide, dyestuff, medicine, food, used to complete the process of vulcanization, nitrification, hydrogenation, hydrocarbonization, polymerization, condensation, etc. The reactor is composed of tank, cover, stirrer, jacket, half pipe, coil, support and transmission device, shaft sealing device, etc. The material and opening can be made according to the user's process requirements.

High Pressure stainless steel Reactor are divided into open and closed types. As the volume of the reaction kettle increases, more closed types are chosen to ensure the compactness of the chemical reactor stainless steel. When selecting, users must choose the model based on their own usage needs (it can be processed according to the user's drawings, non-standard customization)

chemical reactor stainless steel Type: open type reactor, closed type reactor

Material: Carbon steel, low alloy steel, stainless steel, duplex stainless steel, and various composite plate materials

Heating/Cooling: water, steam, heat transfer oil

Technical Parameters

|

INNER VESSE |

JACKET | |

| MATERIAL | Stainless Steel 304/316 | Stainless Steel 304/316 |

| DESIGN PRESSURE(Mpa) | Customized | Customized |

| WORKING TEMPERATURE(℃) | -196~430 | |

Advantages

Features: Fast heating, high temperature resistance, corrosion resistance, hygiene, and no environmental pollution

Applicable Media: Various concentrations of inorganic acids, organic acids, organic solvents, and weakly alkaline solvents

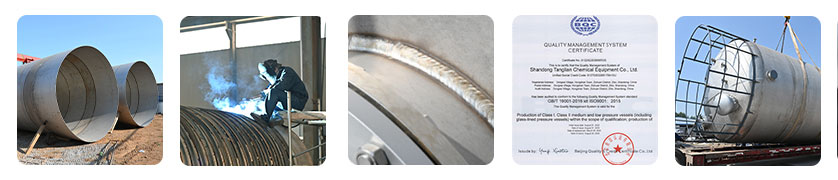

Factory Scenes

Shandong Tanglian Heavy Industrial Group , one of the longest established factories for Chemical reactors / Chemical vessels in China .

We have ISO , SGS , CE ,EU Welder Approval Test Certificate for our company , products and workers .

We mainly focus on below products

Chemical reactor , Storage / Receiving / Buffer tank

Column / Tower section , Pipe line

Heat exchanger / condenser , Evaporator

Main material of our equipment :

Glass Lining , PTFE,ETFE,PFA Lining

Stainless Steel , Carbon Steel , Hastelloy , DP Steel

Company Products

Shipping & Installation

International Market

Categories

News

Contact Us

E-mail: service@chinareactor.com

Add: Hongshan Town Industrial Park, Chongzheng Road, Zichuan District, Zibo City, Shandong Province