Industry news

Guide for selection of glass-lined agitators

The glass-lined agitator is made by firing at a high temperature of about 900 ℃, so that the corrosion-resistant glass is closely adhered to the metal surface. It has good corrosion resistance, smooth surface, wear resistance, and certain thermal stability, and is widely used in chemical, metallurgical rubber, petroleum and other industries.

Since the liquid flow conditions of different types of mixing processes have different requirements for agitators, and one type of agitator can only have good effects on one or several types of mixing operations, different types of mixing can be selected according to their own needs to achieve the best results.

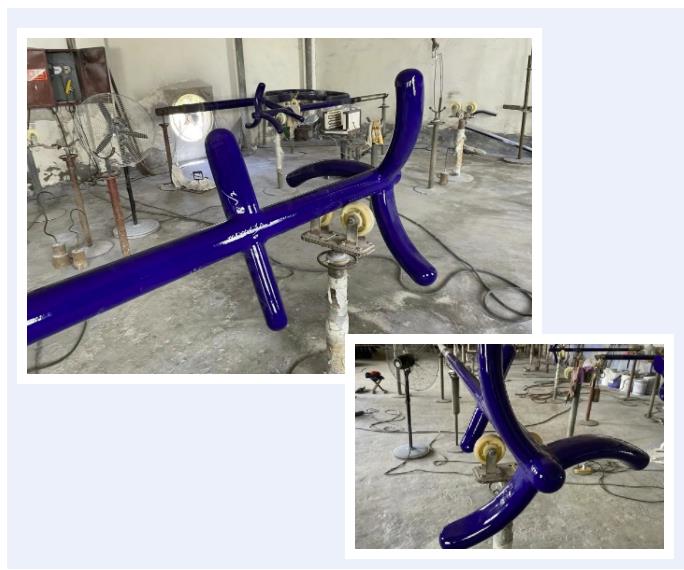

1. Glass lining anchor mixing

The glass-lined anchor type and frame type agitators belong to the same type of agitator, and the frame type can only be considered as the reinforced type of anchor type. This type of mixing is suitable for the mixing of high viscosity materials, which can make the whole material in the container agitate without dead angle.

This type of agitator is generally designed to mix at low speed, and the rotating speed is generally ≤ 80r/min, belonging to mild mixing. When it is used in the coarse crystallization process, it is beneficial to grain growth and improve the yield of crystal in the next process of filtration. It is also suitable for heat transfer operation.

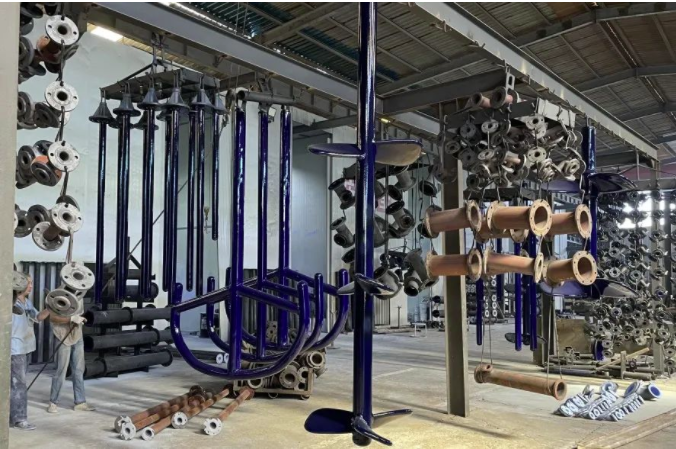

2. Glass-lined impeller mixing

The glass-lined impeller agitator (also known as the three-blade backswept agitator internationally) is characterized by simple structure, strong output performance, low power consumption, wide application range, and can ensure the overall circulation of the fluid in the container (also known as volume circulation). It is currently the most suitable agitator type for medium and low viscosity materials.

When the rotating speed is 130r/min, the circulating capacity is the largest and the unit power consumed is the smallest, with a wide range of applications. The glass-lined impeller agitator has good effects on homogeneous mixing, solid-liquid suspension, gas-liquid mixing, heterogeneous dispersion and other operations. It is characterized by strong stirring which can form a large volume circulation and has a certain shear effect.

3. Glass-lined paddle stirring

The rotating speed of paddle agitator is generally 80r/min and 125r/min, which belongs to slow stirring. Paddle stirring mainly produces large shear on the liquid in the container. If equipped with appropriate baffles, the liquid will be discharged up and down to a certain extent. However, the stirred liquid has poor convection and circulation, and is generally suitable for the dispersed crystallization operation of low viscosity materials.

4. Glass lined axial flow stirring

The glass-lined axial flow agitator is mainly used for the suspension of solid particles, the dissolution of solids, the dispersion of gases in liquids and the absorption of gases by liquids, the mixing of immiscible liquids, liquid emulsification, suspension polymerization, liquid mixing and other process processes, especially for the solid-liquid suspension operation, with the minimum power consumption.

The stirring liquid flow of the glass-lined axial flow stirrer is a large volume circulation with evenly distributed and mild shearing function. The impeller has strong pumping capacity and can produce uniform axial liquid flow, which can quickly eliminate the non-uniformity of the concentration and temperature of two or more materials in the container, so as to achieve the goal of uniformity quickly.

Categories

News

Contact Us

E-mail: service@chinareactor.com

Add: Hongshan Town Industrial Park, Chongzheng Road, Zichuan District, Zibo City, Shandong Province