Product FAQ

Reason and treatment of enamel flange leakage of reaction kettle

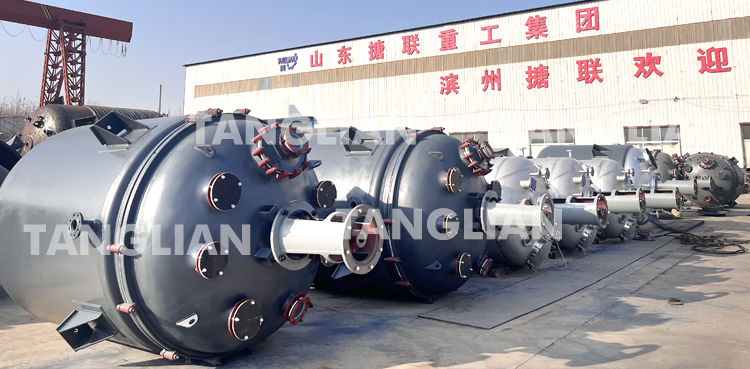

Shandong Tanglian always adhere to the "quality-oriented",with high quality products and perfect after-sales service to win the trust of customers and a high degree of praise, the product sells well at home and abroad.

Chemical plant common equipment reactor is a comprehensive reaction vessel, the operation will be damaged for a variety of reasons, resulting in production was forced to stop. The following describes the reasons and treatment methods for enameled kettle flange leakage:

Fault phenomenon: enamel kettle flange leakage

◆ Reasons for failure:

1, flange porcelain surface damage;

2、Choice of gasket material is unreasonable, the installation joint is not correct, empty position, wrong shift;

3, Loose or insufficient number of clips.

◆Treatment method:

1. Repair, apply anticorrosive paint or resin;

2、According to the process requirements, select the gasket material, the gasket interface should be lapped together and the position should be even;

3、According to the design requirements, there are enough number of cards and they should be tightened.

Need to know more about the content of the reactor, please continue to pay attention to us.

Categories

News

Contact Us

E-mail: service@chinareactor.com

Add: Hongshan Town Industrial Park, Chongzheng Road, Zichuan District, Zibo City, Shandong Province