Industry news

Glass lined reactor enamel characteristics

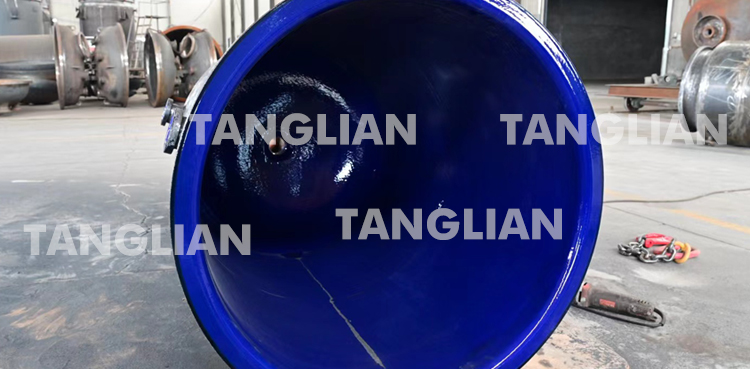

Glass lining is the high silicon content of porcelain enamel coated on the metal surface, through the 950 ℃ enamel firing, so that the porcelain enamel is densely adhered to the surface of the metal iron tire made. Therefore, it has the double advantages of chemical stability and metal strength similar to glass.

The enameling process is a complex physicochemical process, including changes in enamel, changes in steel and the mutual reaction between them.

The enamel of enamel reactor is a glassy substance formed by mixing a variety of mineral raw materials and chemical raw materials according to a certain ratio, after melting or semi-melting. According to the enamel group distribution ratio of different, and can form the bottom glaze and surface glaze.

Glass-lined equipment is widely used in chemical industry, medicine, dyestuff, pesticide, organic synthesis, petroleum, food manufacturing and national defense industry and other industrial production and scientific research in the reaction, evaporation, concentration, synthesis, extraction, polymerization, saponification, mineralization, chlorination, nitrification, etc., in lieu of expensive stainless steel and non-ferrous metals. Corrosion resistance: for various concentrations of inorganic acids, organic acids, organic solvents and weak bases and other media have strong corrosion resistance. But for strong alkali, hydrofluoric acid and fluoride ion-containing media, as well as temperature greater than 180 ℃, concentration greater than 30% of the phosphoric acid is not applicable.

Glass-lined equipment mainly includes reactor, storage tank, distillation tank, condenser and so on.

Categories

News

Contact Us

E-mail: service@chinareactor.com

Add: Hongshan Town Industrial Park, Chongzheng Road, Zichuan District, Zibo City, Shandong Province